Note

Go to the end to download the full example code.

LS-Dyna analysis#

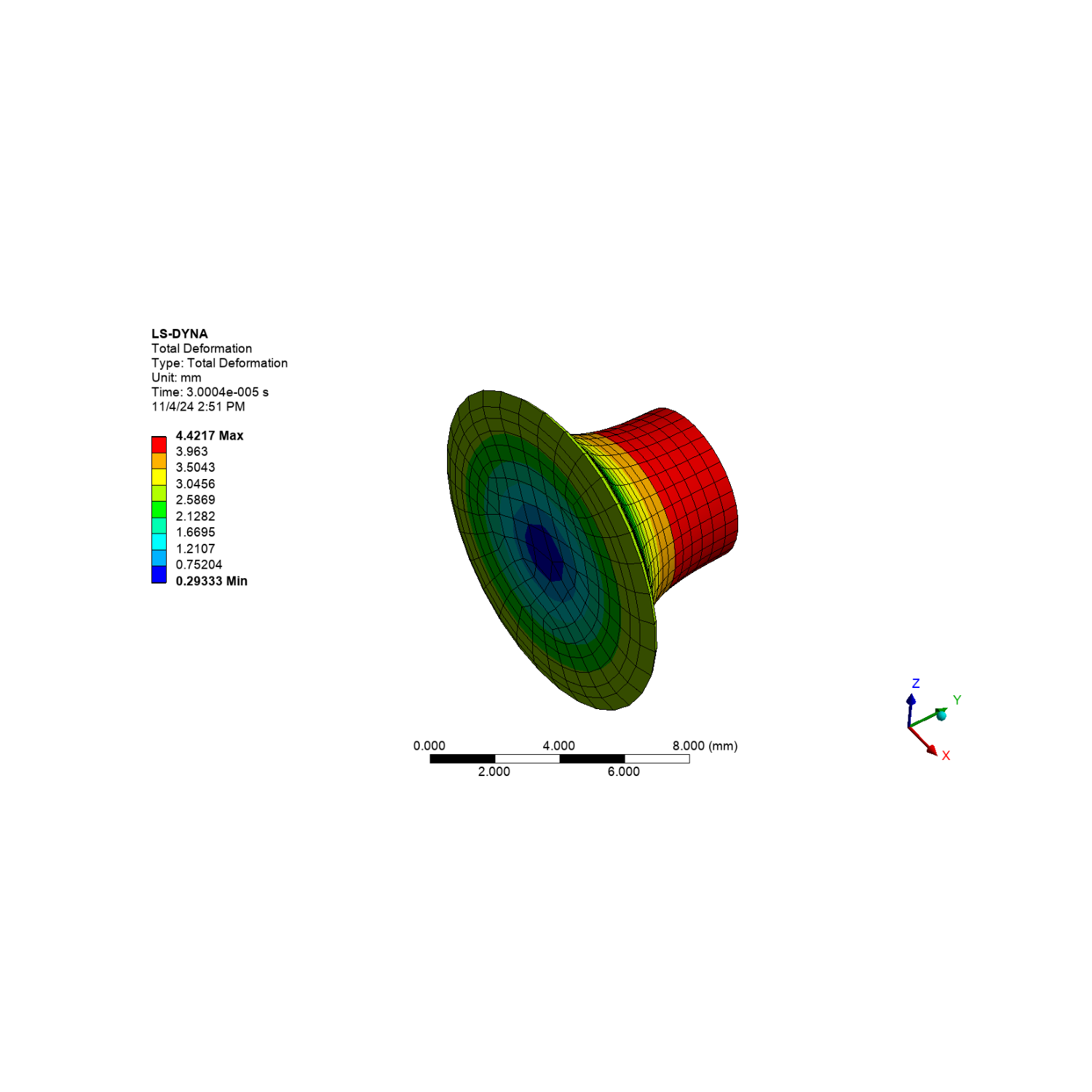

Using supplied files, this example shows how to insert an LS-Dyna analysis into a new Mechanical session and execute a sequence of Python scripting commands that define and solve the analysis. Deformation results are then reported and plastic strain (EPS) animation is exported in the project directory.

Download required files#

Download the required files. Print the file path for the geometry file.

import os

from PIL import Image

from ansys.mechanical.core import launch_mechanical

from ansys.mechanical.core.examples import download_file

from matplotlib import image as mpimg

from matplotlib import pyplot as plt

from matplotlib.animation import FuncAnimation

geometry_path = download_file("example_08_Taylor_Bar.agdb", "pymechanical", "00_basic")

print(f"Downloaded the geometry file to: {geometry_path}")

Downloaded the geometry file to: /home/runner/.local/share/ansys_mechanical_core/examples/example_08_Taylor_Bar.agdb

Launch mechanical#

Launch a new Mechanical session in batch, setting cleanup_on_exit to

False. To close this Mechanical session when finished, this example

must call the mechanical.exit() method.

mechanical = launch_mechanical(batch=True, cleanup_on_exit=False)

print(mechanical)

Ansys Mechanical [Ansys Mechanical Enterprise]

Product Version:252

Software build date: 06/13/2025 11:25:56

Initialize variable for workflow#

Set the part_file_path variable on the server for later use.

Make this variable compatible for Windows, Linux, and Docker containers.

project_directory = mechanical.project_directory

print(f"project directory = {project_directory}")

project_directory = project_directory.replace("\\", "\\\\")

mechanical.run_python_script(f"project_directory='{project_directory}'")

# Upload the file to the project directory.

mechanical.upload(file_name=geometry_path, file_location_destination=project_directory)

# Build the path relative to project directory.

base_name = os.path.basename(geometry_path)

combined_path = os.path.join(project_directory, base_name)

part_file_path = combined_path.replace("\\", "\\\\")

mechanical.run_python_script(f"part_file_path='{part_file_path}'")

project directory = /tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/

Uploading example_08_Taylor_Bar.agdb to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/.: 0%| | 0.00/2.27M [00:00<?, ?B/s]

Uploading example_08_Taylor_Bar.agdb to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/.: 100%|██████████| 2.27M/2.27M [00:00<00:00, 978MB/s]

''

Download required material files#

Download the required file. Print the file path for the material file.

mat_st_path = download_file("example_08_Taylor_Bar_Mat.xml", "pymechanical", "00_basic")

print(f"Downloaded the material file to: {mat_st_path}")

# Upload the file to the project directory.

mechanical.upload(file_name=mat_st_path, file_location_destination=project_directory)

# Build the path relative to project directory.

base_name = os.path.basename(mat_st_path)

combined_path = os.path.join(project_directory, base_name)

mat_file_path = combined_path.replace("\\", "\\\\")

mechanical.run_python_script(f"mat_file_path='{mat_file_path}'")

# Verify the path

result = mechanical.run_python_script("part_file_path")

print(f"part_file_path on server: {result}")

Downloaded the material file to: /home/runner/.local/share/ansys_mechanical_core/examples/example_08_Taylor_Bar_Mat.xml

Uploading example_08_Taylor_Bar_Mat.xml to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/.: 0%| | 0.00/13.6k [00:00<?, ?B/s]

Uploading example_08_Taylor_Bar_Mat.xml to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/.: 100%|██████████| 13.6k/13.6k [00:00<00:00, 55.8MB/s]

part_file_path on server: /tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/example_08_Taylor_Bar.agdb

Run the script#

Run the Mechanical script to attach the geometry and set up and solve the analysis.

mech_act_code = """

import os

import json

# Import Taylor bar geometry

geometry_import_group = Model.GeometryImportGroup

geometry_import = geometry_import_group.AddGeometryImport()

geometry_import_format = Ansys.Mechanical.DataModel.Enums.GeometryImportPreference.Format.Automatic

geometry_import.Import(part_file_path, geometry_import_format, None)

Model.AddLSDynaAnalysis()

analysis = Model.Analyses[0]

ExtAPI.Application.ActiveUnitSystem = MechanicalUnitSystem.StandardNMMton

ExtAPI.Application.ActiveAngleUnit = AngleUnitType.Radian

# Assign the material

MAT = ExtAPI.DataModel.Project.Model.Materials

MAT.Import(mat_file_path)

ExtAPI.DataModel.Project.Model.Geometry.Children[0].Children[0].Material = "Bullet"

# Add Coordinate system

cs = Model.CoordinateSystems

lcs = cs.AddCoordinateSystem()

lcs.Origin = [10.0, 1.5, -10.0]

lcs.PrimaryAxis = CoordinateSystemAxisType.PositiveZAxis

lcs.PrimaryAxisDefineBy = CoordinateSystemAlignmentType.GlobalY

lcs.OriginDefineBy = CoordinateSystemAlignmentType.Fixed

solver = analysis.Solver

solver.Properties['Step Controls/Endtime'].Value = 3.0E-5

analysis.Activate()

# Add Rigid Wall

rigid_wall = analysis.CreateLoadObject("Rigid Wall", "LSDYNA")

rigid_wall.Properties["Coordinate System"].Value = lcs.ObjectId

ExtAPI.DataModel.Tree.Refresh()

# Adding initial velocity

ic = ExtAPI.DataModel.GetObjectsByName("Initial Conditions")[0]

vel = ic.InsertVelocity()

selection = ExtAPI.SelectionManager.CreateSelectionInfo(SelectionTypeEnum.GeometryEntities)

selection.Ids = [ExtAPI.DataModel.GeoData.Assemblies[0].Parts[0].Bodies[0].Id]

vel.Location = selection

vel.DefineBy = LoadDefineBy.Components

vel.YComponent = Quantity(-280000, ExtAPI.DataModel.CurrentUnitFromQuantityName("Velocity"))

# By default quadratic element order in Mechanical - LSDyna supports only Linear

mesh = ExtAPI.DataModel.GetObjectsByName("Mesh")[0]

mesh.ElementOrder = ElementOrder.Linear

mesh.ElementSize = Quantity(0.5, "mm")

# Solve

analysis.Solution.Solve()

# Post-processing

eps = analysis.Solution.AddUserDefinedResult()

eps.Expression = "EPS"

eps.EvaluateAllResults()

eps_max = eps.Maximum

eps_min = eps.Minimum

total_deformation = analysis.Solution.AddTotalDeformation()

total_deformation.EvaluateAllResults()

# Set Camera

Graphics.Camera.FocalPoint = Point([9.0521184381880495,

2.9680547361873595,

-11.52925245328758], 'mm')

Graphics.Camera.ViewVector = Vector3D(0.5358281613965048,

-0.45245539014067604,

0.71286204933850261)

Graphics.Camera.UpVector = Vector3D(-0.59927496479653264,

0.39095266724498329,

0.69858823962485084)

Graphics.Camera.SceneHeight = Quantity(14.66592829617538, 'mm')

Graphics.Camera.SceneWidth = Quantity(8.4673776497126063, 'mm')

# Set Scale factor

true_scale = MechanicalEnums.Graphics.DeformationScaling.True

Graphics.ViewOptions.ResultPreference.DeformationScaling = true_scale

Graphics.ViewOptions.ResultPreference.DeformationScaleMultiplier = 1

# Export an animation

mechdir = ExtAPI.DataModel.AnalysisList[0].WorkingDir

eps.Activate()

animation_export_format = GraphicsAnimationExportFormat.GIF

settings_720p = Ansys.Mechanical.Graphics.AnimationExportSettings()

settings_720p.Width = 1280

settings_720p.Height = 720

anim_file_path = os.path.join(mechdir, "taylor_bar.gif")

eps.ExportAnimation(

anim_file_path, animation_export_format, settings_720p

)

# Set the isometric view and zoom to fit

settings_720p = Ansys.Mechanical.Graphics.GraphicsImageExportSettings()

settings_720p.Resolution = (GraphicsResolutionType.EnhancedResolution)

settings_720p.Background = GraphicsBackgroundType.White

settings_720p.Width = 1280

settings_720p.Height = 720

settings_720p.CurrentGraphicsDisplay = False

total_deformation.Activate()

image_path = os.path.join(mechdir, "totaldeformation.png")

Graphics.ExportImage(image_path, GraphicsImageExportFormat.PNG, settings_720p)

dir_deformation_details = {

"Minimum": str(eps_max),

"Maximum": str(eps_min)

}

json.dumps(dir_deformation_details)

"""

output = mechanical.run_python_script(mech_act_code)

print(output)

# image_directory_modified = project_directory.replace("\\", "\\\\")

mechanical.run_python_script(f"image_dir=ExtAPI.DataModel.AnalysisList[0].WorkingDir")

# Verify the path for image directory.

result_image_dir_server = mechanical.run_python_script(f"image_dir")

print(f"Images are stored on the server at: {result_image_dir_server}")

{"Maximum": "0", "Minimum": "2.7366569995880128"}

Images are stored on the server at: /tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/ExplicitDynamics/

Download output file from solve and print contents#

Download the solve.out file from the server to the current working

directory and print the contents. Remove the solve.out file.

def get_solve_out_path(mechanical):

"""Get the solve out path and return."""

solve_out_path = ""

for file_path in mechanical.list_files():

if file_path.find("solve.out") != -1:

solve_out_path = file_path

break

return solve_out_path

def write_file_contents_to_console(path):

"""Write file contents to console."""

with open(path, "rt") as file:

for line in file:

print(line, end="")

print("Getting solve out path")

solve_out_path = get_solve_out_path(mechanical)

print(f"Solve out path (on remote machine): {solve_out_path}")

if solve_out_path != "":

current_working_directory = os.getcwd()

print(f"Performing download request...")

mechanical.download(solve_out_path, target_dir=current_working_directory)

solve_out_local_path = os.path.join(current_working_directory, "solve.out")

print(f"File downloaded locally at {solve_out_local_path}")

write_file_contents_to_console(solve_out_local_path)

print("Printed output to console")

os.remove(solve_out_local_path)

Getting solve out path

Solve out path (on remote machine): /tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/ExplicitDynamics/solve.out

Performing download request...

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/ExplicitDynamics/solve.out to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/solve.out: 0%| | 0.00/13.7k [00:00<?, ?B/s]

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/ExplicitDynamics/solve.out to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/solve.out: 100%|██████████| 13.7k/13.7k [00:00<00:00, 74.6MB/s]

File downloaded locally at /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/solve.out

License option : check ansys licenses only

***************************************************************

* ANSYS LEGAL NOTICES *

***************************************************************

* *

* Copyright 1971-2025 ANSYS, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of ANSYS, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the ANSYS, Inc. online documentation or the ANSYS, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* ANSYS, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* ANSYS, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the ANSYS, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the ANSYS, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

Date: 01/05/2026 Time: 20:51:41

___________________________________________________

| |

| LS-DYNA, A Program for Nonlinear Dynamic |

| Analysis of Structures in Three Dimensions |

| Date : 05/14/2025 Time: 11:18:04 |

| Version : smp s R14 |

| Revision: R14.1.1-16-gfadfb49b17 |

| AnLicVer: 2025 R2 (20250506+dl-73-g4dde854) |

| |

| Features enabled in this version: |

| Shared Memory Parallel |

| FFTW (multi-dimensional FFTW Library) |

| ANSYSLIC enabled |

| |

| Platform : Xeon64 System |

| OS Level : Linux 3.10.0 uum |

| Compiler : Intel Fortran Compiler 19.0 SSE2 |

| Hostname : 3cbdcfa4f10a |

| Precision : Single precision (I4R4) |

| |

| Unauthorized use infringes Ansys Inc. copyrights |

|___________________________________________________|

> i=input.k S=input.intfor x=70 NCPU=1

[license/info] Successfully checked out 1 of "dyna_solver_core".

[license/info] --> Checkout ID: 3cbdcfa4f10a-root-113-000163 (days left: 277)

[license/info] --> Customer ID: 0

[license/info] Successfully started "LSDYNA (Core-based License)".

Executing with ANSYS license

Scale factor for file size = 70

new file size = 18350080

Use this scale factor on all restarts.

Command line options: i=input.k

S=input.intfor

x=70

NCPU=1

Input file: input.k

The native file format : 32-bit small endian

Memory size from default : 100000000

on UNIX computers note the following change:

ctrl-c interrupts ls-dyna and prompts for a sense switch.

type the desired sense switch: sw1., sw2., etc. to continue

the execution. ls-dyna will respond as explained in the users manual

type response

----- ------------------------------------------------------------

quit ls-dyna terminates.

stop ls-dyna terminates.

sw1. a restart file is written and ls-dyna terminates.

sw2. ls-dyna responds with time and cycle numbers.

sw3. a restart file is written and ls-dyna continues calculations.

sw4. a plot state is written and ls-dyna continues calculations.

sw5. ls-dyna enters interactive graphics phase.

swa. ls-dyna flushes all output i/o buffers.

swb. a dynain is written and ls-dyna continues calculations.

swc. a restart and dynain are written and ls-dyna continues calculations.

swd. a restart and dynain are written and ls-dyna terminates.

swe. stop dynamic relaxation just as though convergence

endtime=time change the termination time

lpri toggle implicit lin. alg. solver output on/off.

nlpr toggle implicit nonlinear solver output on/off.

iter toggle implicit output to d3iter database on/off.

prof output timing data to messag and continue.

conv force implicit nonlinear convergence for current time step.

ttrm terminate implicit time step, reduce time step, retry time step.

rtrm terminate implicit at end of current time step.

******** notice ******** notice ******** notice ********

* *

* This is the LS-DYNA Finite Element code. *

* *

* Neither LST nor the authors assume any responsibility for *

* the validity, accuracy, or applicability of any results *

* obtained from this system. Users must verify their own *

* results. *

* *

* LST endeavors to make the LS-DYNA code as complete, *

* accurate and easy to use as possible. *

* Suggestions and comments are welcomed. Please report any *

* errors encountered in either the documentation or results *

* immediately to LST through your site focus. *

* *

* Copyright (C) 1990-2021 *

* by Livermore Software Technology, LLC *

* All rights reserved *

* *

******** notice ******** notice ******** notice ********

Beginning of keyword reader 01/05/26 20:51:44

Memory required to process keyword : 319296

Additional dynamic memory required : 573821

input of data is completed

initial kinetic energy = 0.68292406E+05

Memory required to begin solution : 320K

Additional dynamically allocated memory: 787K

Total: 1107K

initialization completed

1 t 0.0000E+00 dt 1.98E-08 flush i/o buffers 01/05/26 20:51:44

1 t 0.0000E+00 dt 1.98E-08 write d3plot file 01/05/26 20:51:44

cpu time per zone cycle............ 527 nanoseconds

average cpu time per zone cycle.... 566 nanoseconds

average clock time per zone cycle.. 624 nanoseconds

estimated total cpu time = 4 sec ( 0 hrs 0 mins)

estimated cpu time to complete = 4 sec ( 0 hrs 0 mins)

estimated total clock time = 7 sec ( 0 hrs 0 mins)

estimated clock time to complete = 4 sec ( 0 hrs 0 mins)

termination time = 3.000E-05

termination cycle = 10000000

77 t 1.4949E-06 dt 1.98E-08 write d3plot file 01/05/26 20:51:45

153 t 2.9937E-06 dt 1.97E-08 write d3plot file 01/05/26 20:51:45

229 t 4.4954E-06 dt 1.99E-08 write d3plot file 01/05/26 20:51:45

304 t 5.9808E-06 dt 2.00E-08 write d3plot file 01/05/26 20:51:45

380 t 7.4942E-06 dt 1.98E-08 write d3plot file 01/05/26 20:51:45

461 t 8.9899E-06 dt 1.59E-08 write d3plot file 01/05/26 20:51:45

564 t 1.0494E-05 dt 1.36E-08 write d3plot file 01/05/26 20:51:45

689 t 1.1990E-05 dt 1.07E-08 write d3plot file 01/05/26 20:51:46

836 t 1.3497E-05 dt 9.66E-09 write d3plot file 01/05/26 20:51:46

1003 t 1.4998E-05 dt 8.72E-09 write d3plot file 01/05/26 20:51:46

1190 t 1.6499E-05 dt 7.94E-09 write d3plot file 01/05/26 20:51:46

1392 t 1.7994E-05 dt 7.34E-09 write d3plot file 01/05/26 20:51:47

1604 t 1.9498E-05 dt 6.63E-09 write d3plot file 01/05/26 20:51:47

1827 t 2.0996E-05 dt 6.76E-09 write d3plot file 01/05/26 20:51:48

2058 t 2.2500E-05 dt 6.30E-09 write d3plot file 01/05/26 20:51:48

2289 t 2.3999E-05 dt 6.27E-09 write d3plot file 01/05/26 20:51:48

2524 t 2.5494E-05 dt 6.30E-09 write d3plot file 01/05/26 20:51:49

2762 t 2.6996E-05 dt 6.32E-09 write d3plot file 01/05/26 20:51:49

2992 t 2.8499E-05 dt 6.71E-09 write d3plot file 01/05/26 20:51:49

3225 t 2.9998E-05 dt 6.33E-09 write d3plot file 01/05/26 20:51:50

*** termination time reached ***

3225 t 3.0004E-05 dt 6.33E-09 write d3dump01 file 01/05/26 20:51:50

3225 t 3.0004E-05 dt 6.33E-09 write d3plot file 01/05/26 20:51:50

N o r m a l t e r m i n a t i o n 01/05/26 20:51:50

Memory required to complete solution : 320K

Additional dynamically allocated memory: 789K

Total: 1108K

T i m i n g i n f o r m a t i o n

CPU(seconds) %CPU Clock(seconds) %Clock

----------------------------------------------------------------

Keyword Processing ... 3.6948E-02 0.65 3.6949E-02 0.41

KW Reading ......... 2.5677E-02 0.45 2.5677E-02 0.29

KW Writing ......... 2.3096E-03 0.04 2.3100E-03 0.03

Initialization ....... 7.6381E-02 1.35 3.4095E+00 37.95

Init Proc Phase 1 .. 1.0232E-02 0.18 1.1103E-02 0.12

Init Proc Phase 2 .. 3.2162E-03 0.06 4.0620E-03 0.05

Init solver .......... 6.6183E-05 0.00 6.7000E-05 0.00

Element processing ... 4.6497E+00 82.32 4.6497E+00 51.75

Solids ............. 4.2589E+00 75.41 4.2577E+00 47.39

Shells ............. 1.0080E-02 0.18 1.1291E-02 0.13

ISO Shells ......... 2.8661E-03 0.05 3.5400E-03 0.04

E Other ............ 1.0748E-02 0.19 1.0974E-02 0.12

Binary databases ..... 1.9558E-02 0.35 1.9868E-02 0.22

ASCII database ....... 1.5805E-01 2.80 1.5782E-01 1.76

Contact algorithm .... 9.6876E-03 0.17 9.7050E-03 0.11

Rigid Bodies ......... 4.8517E-03 0.09 4.8170E-03 0.05

Time step size ....... 4.4891E-03 0.08 4.5610E-03 0.05

Rigid wall ........... 2.9995E-01 5.31 2.9923E-01 3.33

Group force file ..... 3.7746E-03 0.07 4.5290E-03 0.05

Others ............... 1.0813E-02 0.19 1.0793E-02 0.12

Misc. 1 .............. 2.6706E-01 4.73 2.7094E-01 3.02

Scale Masses ....... 2.5079E-03 0.04 2.5300E-03 0.03

Force Constraints .. 2.5356E-03 0.04 2.4860E-03 0.03

Force to Accel ..... 4.1695E-02 0.74 4.1361E-02 0.46

Update RB nodes .... 2.7905E-03 0.05 3.1420E-03 0.03

Misc. 2 .............. 7.1044E-02 1.26 7.0266E-02 0.78

Misc. 3 .............. 1.0189E-02 0.18 1.0073E-02 0.11

Misc. 4 .............. 2.5494E-02 0.45 2.5596E-02 0.28

Timestep Init ...... 1.4182E-02 0.25 1.3929E-02 0.16

Apply Loads ........ 6.1027E-03 0.11 6.2050E-03 0.07

----------------------------------------------------------------

T o t a l s 5.6480E+00 100.00 8.9844E+00 100.00

Problem time = 3.0004E-05

Problem cycle = 3225

Total CPU time = 6 seconds ( 0 hours 0 minutes 6 seconds)

CPU time per zone cycle = 360.467 nanoseconds

Clock time per zone cycle= 360.679 nanoseconds

Number of CPU's 1

NLQ used/max 112/ 112

Start time 01/05/2026 20:51:44

End time 01/05/2026 20:51:50

Elapsed time 6 seconds for 3225 cycles using 1 SMP thread

( 0 hour 0 minute 6 seconds)

N o r m a l t e r m i n a t i o n 01/05/26 20:51:50

Printed output to console

Get image and display#

def get_image_path(image_name):

return os.path.join(result_image_dir_server, image_name)

def display_image(path):

print(f"Printing {path} using matplotlib")

image1 = mpimg.imread(path)

plt.figure(figsize=(15, 15))

plt.axis("off")

plt.imshow(image1)

plt.show()

image_name = "totaldeformation.png"

image_path_server = get_image_path(image_name)

if image_path_server != "":

current_working_directory = os.getcwd()

local_file_path_list = mechanical.download(

image_path_server, target_dir=current_working_directory

)

image_local_path = local_file_path_list[0]

print(f"Local image path : {image_local_path}")

display_image(image_local_path)

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/ExplicitDynamics/totaldeformation.png to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/totaldeformation.png: 0%| | 0.00/131k [00:00<?, ?B/s]

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/ExplicitDynamics/totaldeformation.png to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/totaldeformation.png: 100%|██████████| 131k/131k [00:00<00:00, 681MB/s]

Local image path : /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/totaldeformation.png

Printing /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/totaldeformation.png using matplotlib

Download gif and display#

animation_name = "taylor_bar.gif"

animation_server = get_image_path(animation_name)

def update(frame):

gif.seek(frame)

img.set_array(gif.convert("RGBA"))

return [img]

if image_path_server != "":

current_working_directory = os.getcwd()

local_file_path_list = mechanical.download(

animation_server, target_dir=current_working_directory

)

image_local_path = local_file_path_list[0]

print(f"Local image path : {image_local_path}")

gif = Image.open(image_local_path)

fig, ax = plt.subplots(figsize=(16, 9))

ax.axis("off")

img = ax.imshow(gif.convert("RGBA"))

ani = FuncAnimation(

fig, update, frames=range(gif.n_frames), interval=100, repeat=True, blit=True

)

plt.show()

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/ExplicitDynamics/taylor_bar.gif to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/taylor_bar.gif: 0%| | 0.00/340k [00:00<?, ?B/s]

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechD968/Project_Mech_Files/ExplicitDynamics/taylor_bar.gif to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/taylor_bar.gif: 100%|██████████| 340k/340k [00:00<00:00, 729MB/s]

Local image path : /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/taylor_bar.gif

Close mechanical#

Close the mechanical instance.

print("Closing mechanical...")

mechanical.exit()

print("Mechanical closed!")

Closing mechanical...

Mechanical closed!

Total running time of the script: (0 minutes 23.853 seconds)