Note

Go to the end to download the full example code.

Bolt Pretension#

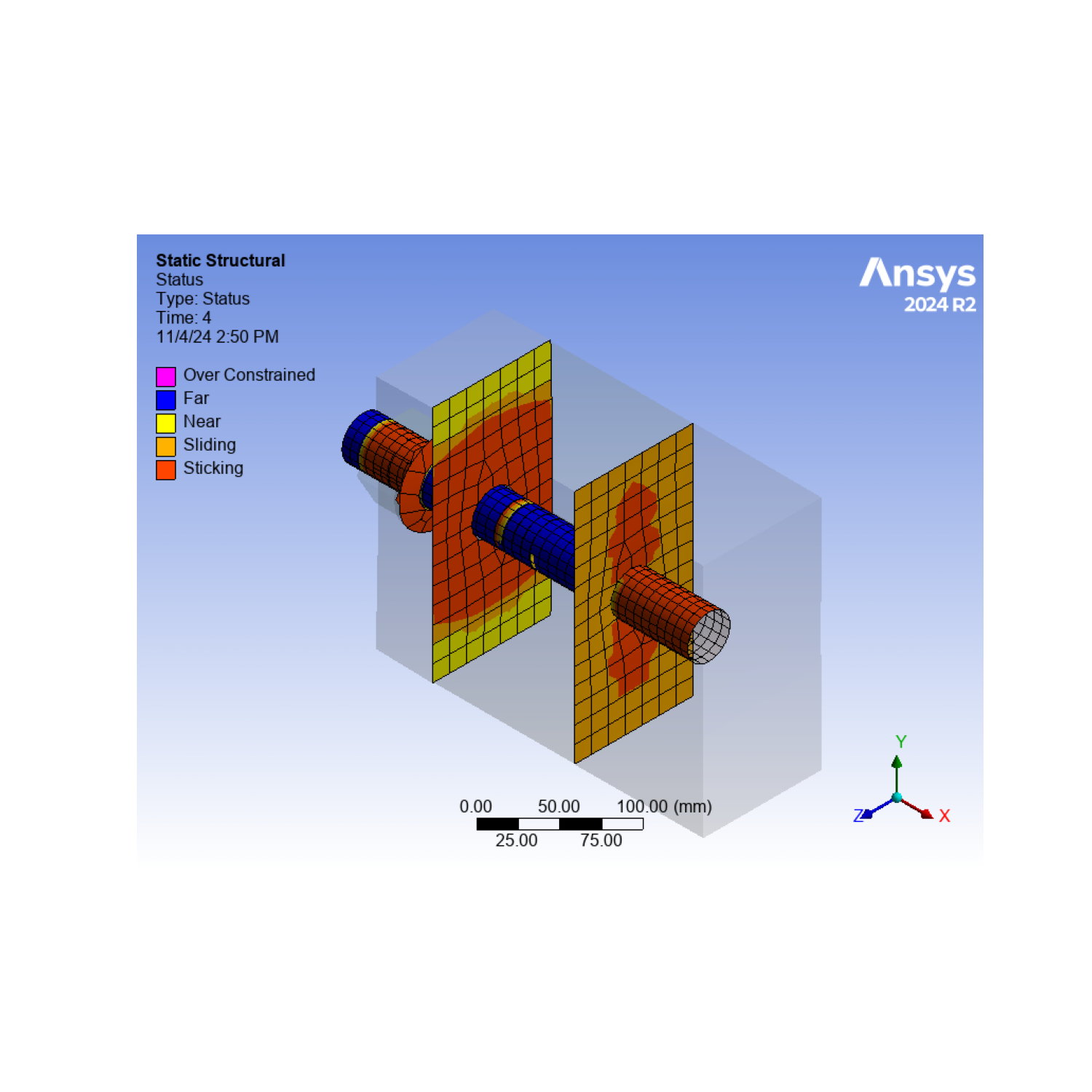

This example demonstrates how to insert a Static Structural analysis into a new Mechanical session and execute a sequence of Python scripting commands that define and solve a bolt-pretension analysis. Scripts then evaluate the following results: deformation, equivalent stresses, contact, and bolt

Import necessary libraries#

import os

from ansys.mechanical.core import launch_mechanical

from ansys.mechanical.core.examples import download_file

from matplotlib import image as mpimg

from matplotlib import pyplot as plt

Launch mechanical#

Launch a new Mechanical session in batch, setting the cleanup_on_exit

argument to False. To close this Mechanical session when finished,

this example must call the mechanical.exit() method.

mechanical = launch_mechanical(batch=True, cleanup_on_exit=False)

print(mechanical)

Ansys Mechanical [Ansys Mechanical Enterprise]

Product Version:252

Software build date: 06/13/2025 11:25:56

Initialize variable for workflow#

Set the part_file_path variable on the server for later use.

Make this variable compatible for Windows, Linux, and Docker containers.

project_directory = mechanical.project_directory

print(f"project directory = {project_directory}")

project directory = /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/

Download required geometry file#

Download the required file. Print the file path for the geometry file.

geometry_path = download_file(

"example_06_bolt_pret_geom.agdb", "pymechanical", "00_basic"

)

print(f"Downloaded the geometry file to: {geometry_path}")

Downloaded the geometry file to: /home/runner/.local/share/ansys_mechanical_core/examples/example_06_bolt_pret_geom.agdb

Upload the file to the project directory

mechanical.upload(file_name=geometry_path, file_location_destination=project_directory)

Uploading example_06_bolt_pret_geom.agdb to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/.: 0%| | 0.00/2.52M [00:00<?, ?B/s]

Uploading example_06_bolt_pret_geom.agdb to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/.: 100%|██████████| 2.52M/2.52M [00:00<00:00, 449MB/s]

'example_06_bolt_pret_geom.agdb'

Build the path relative to project directory and verify

base_name = os.path.basename(geometry_path)

combined_path = os.path.join(project_directory, base_name)

part_file_path = combined_path.replace("\\", "\\\\")

mechanical.run_python_script(f"part_file_path='{part_file_path}'")

result = mechanical.run_python_script("part_file_path")

print(f"Geometry file on server: {result}")

Geometry file on server: /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/example_06_bolt_pret_geom.agdb

Download required material file#

Download the required file. Print the file path for the material file

mat_cop_path = download_file("example_06_Mat_Copper.xml", "pymechanical", "00_basic")

print(f"Downloaded the material file to: {mat_cop_path}")

mat_st_path = download_file("example_06_Mat_Steel.xml", "pymechanical", "00_basic")

print(f"Downloaded the material file to: {mat_st_path}")

Downloaded the material file to: /home/runner/.local/share/ansys_mechanical_core/examples/example_06_Mat_Copper.xml

Downloaded the material file to: /home/runner/.local/share/ansys_mechanical_core/examples/example_06_Mat_Steel.xml

Upload the file to the project directory

mechanical.upload(file_name=mat_cop_path, file_location_destination=project_directory)

mechanical.upload(file_name=mat_st_path, file_location_destination=project_directory)

Uploading example_06_Mat_Copper.xml to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/.: 0%| | 0.00/5.00k [00:00<?, ?B/s]

Uploading example_06_Mat_Copper.xml to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/.: 100%|██████████| 5.00k/5.00k [00:00<00:00, 18.3MB/s]

Uploading example_06_Mat_Steel.xml to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/.: 0%| | 0.00/5.00k [00:00<?, ?B/s]

Uploading example_06_Mat_Steel.xml to dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/.: 100%|██████████| 5.00k/5.00k [00:00<00:00, 13.9MB/s]

'example_06_Mat_Steel.xml'

Build the path relative to project directory and verify

base_name = os.path.basename(mat_cop_path)

combined_path = os.path.join(project_directory, base_name)

mat_Copper_file_path = combined_path.replace("\\", "\\\\")

mechanical.run_python_script(f"mat_Copper_file_path='{mat_Copper_file_path}'")

base_name = os.path.basename(mat_st_path)

combined_path = os.path.join(project_directory, base_name)

mat_Steel_file_path = combined_path.replace("\\", "\\\\")

mechanical.run_python_script(f"mat_Steel_file_path='{mat_Steel_file_path}'")

result = mechanical.run_python_script("mat_Copper_file_path")

print(f"mat_Copper_file_path on server: {result}")

result = mechanical.run_python_script("mat_Steel_file_path")

print(f"mat_Steel_file_path on server: {result}")

mat_Copper_file_path on server: /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/example_06_Mat_Copper.xml

mat_Steel_file_path on server: /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/example_06_Mat_Steel.xml

Run the script#

Run the Mechanical script to attach the geometry and set up and solve the analysis

output = mechanical.run_python_script(

"""

import json

import os

# Read geometry and material information.

geometry_import_group = Model.GeometryImportGroup

geometry_import = geometry_import_group.AddGeometryImport()

geometry_import_format = Ansys.Mechanical.DataModel.Enums.GeometryImportPreference.\

Format.Automatic

geometry_import_preferences = Ansys.ACT.Mechanical.Utilities.GeometryImportPreferences()

geometry_import_preferences.ProcessNamedSelections = True

geometry_import_preferences.ProcessCoordinateSystems = True

geometry_import.Import(part_file_path,geometry_import_format,geometry_import_preferences)

# Import materials.

MAT = ExtAPI.DataModel.Project.Model.Materials

MAT.Import(mat_Copper_file_path)

MAT.Import(mat_Steel_file_path)

Model.AddStaticStructuralAnalysis()

STAT_STRUC = Model.Analyses[0]

STAT_STRUC_SOLN = STAT_STRUC.Solution

STAT_STRUC_ANA_SETTING = STAT_STRUC.Children[0]

# Set up the unit system.

ExtAPI.Application.ActiveUnitSystem = MechanicalUnitSystem.StandardNMM

# Store all main tree nodes as variables.

MODEL = ExtAPI.DataModel.Project.Model

GEOM = ExtAPI.DataModel.Project.Model.Geometry

CONN_GRP = ExtAPI.DataModel.Project.Model.Connections

CS_GRP = ExtAPI.DataModel.Project.Model.CoordinateSystems

MSH = ExtAPI.DataModel.Project.Model.Mesh

NS_GRP = ExtAPI.DataModel.Project.Model.NamedSelections

# Store name selection.

block3_block2_cont_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'block3_block2_cont'][0]

block3_block2_targ_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'block3_block2_targ'][0]

shank_block3_targ_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'shank_block3_targ'][0]

shank_block3_cont_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'shank_block3_cont'][0]

block1_washer_cont_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'block1_washer_cont'][0]

block1_washer_targ_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'block1_washer_targ'][0]

washer_bolt_cont_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'washer_bolt_cont'][0]

washer_bolt_targ_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'washer_bolt_targ'][0]

shank_bolt_targ_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'shank_bolt_targ'][0]

shank_bolt_cont_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'shank_bolt_cont'][0]

block2_block1_cont_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'block2_block1_cont'][0]

block2_block1_targ_NS = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'block2_block1_targ'][0]

all_bodies = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'all_bodies'][0]

bodies_5 = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'bodies_5'][0]

shank = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'shank'][0]

shank_face = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'shank_face'][0]

shank_face2 = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'shank_face2'][0]

bottom_surface = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'bottom_surface'][0]

block2_surface = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'block2_surface'][0]

shank_surface = [x for x in ExtAPI.DataModel.Tree.AllObjects

if x.Name == 'shank_surface'][0]

# Assign material to bodies.

SURFACE1=GEOM.Children[0].Children[0]

SURFACE1.Material="Steel"

SURFACE2=GEOM.Children[1].Children[0]

SURFACE2.Material="Copper"

SURFACE3=GEOM.Children[2].Children[0]

SURFACE3.Material="Copper"

SURFACE4=GEOM.Children[3].Children[0]

SURFACE4.Material="Steel"

SURFACE5=GEOM.Children[4].Children[0]

SURFACE5.Material="Steel"

SURFACE6=GEOM.Children[5].Children[0]

SURFACE6.Material="Steel"

# Define coordinate system.

coordinate_systems_17 = Model.CoordinateSystems

coordinate_system_93 = coordinate_systems_17.AddCoordinateSystem()

coordinate_system_93.OriginDefineBy = CoordinateSystemAlignmentType.Fixed

coordinate_system_93.OriginX = Quantity(-195, "mm")

coordinate_system_93.OriginY = Quantity(100, "mm")

coordinate_system_93.OriginZ = Quantity(50, "mm")

coordinate_system_93.PrimaryAxis = CoordinateSystemAxisType.PositiveZAxis

# Change contact settings and add a command snippet to use the Archard Wear Model.

connections = ExtAPI.DataModel.Project.Model.Connections

# Delete existing contacts.

for connection in connections.Children:

if connection.DataModelObjectCategory==DataModelObjectCategory.ConnectionGroup:

connection.Delete()

CONT_REG1 = CONN_GRP.AddContactRegion()

CONT_REG1.SourceLocation = NS_GRP.Children[0]

CONT_REG1.TargetLocation = NS_GRP.Children[1]

CONT_REG1.ContactType=ContactType.Frictional

CONT_REG1.FrictionCoefficient = 0.2

CONT_REG1.SmallSliding = ContactSmallSlidingType.Off

CONT_REG1.UpdateStiffness = UpdateContactStiffness.Never

CMD1=CONT_REG1.AddCommandSnippet()

# Add missing contact keyopt and Archard Wear Model in workbench using a command snippet.

AWM = '''keyopt,cid,9,5

rmodif,cid,10,0.00

rmodif,cid,23,0.001'''

CMD1.AppendText(AWM)

CONTS = CONN_GRP.Children[0]

CONT_REG2 = CONTS.AddContactRegion()

CONT_REG2.SourceLocation = NS_GRP.Children[3]

CONT_REG2.TargetLocation = NS_GRP.Children[2]

CONT_REG2.ContactType=ContactType.Bonded

CONT_REG2.ContactFormulation = ContactFormulation.MPC

CONT_REG3 = CONTS.AddContactRegion()

CONT_REG3.SourceLocation = NS_GRP.Children[4]

CONT_REG3.TargetLocation = NS_GRP.Children[5]

CONT_REG3.ContactType=ContactType.Frictional

CONT_REG3.FrictionCoefficient = 0.2

CONT_REG3.SmallSliding = ContactSmallSlidingType.Off

CONT_REG3.UpdateStiffness = UpdateContactStiffness.Never

CMD3=CONT_REG3.AddCommandSnippet()

# Add missing contact keyopt and Archard Wear Model in workbench using a command snippet.

AWM3 = '''keyopt,cid,9,5

rmodif,cid,10,0.00

rmodif,cid,23,0.001'''

CMD3.AppendText(AWM3)

CONT_REG4 = CONTS.AddContactRegion()

CONT_REG4.SourceLocation = NS_GRP.Children[6]

CONT_REG4.TargetLocation = NS_GRP.Children[7]

CONT_REG4.ContactType=ContactType.Bonded

CONT_REG4.ContactFormulation = ContactFormulation.MPC

CONT_REG5 = CONTS.AddContactRegion()

CONT_REG5.SourceLocation = NS_GRP.Children[9]

CONT_REG5.TargetLocation = NS_GRP.Children[8]

CONT_REG5.ContactType=ContactType.Bonded

CONT_REG5.ContactFormulation = ContactFormulation.MPC

CONT_REG6 = CONTS.AddContactRegion()

CONT_REG6.SourceLocation = NS_GRP.Children[10]

CONT_REG6.TargetLocation = NS_GRP.Children[11]

CONT_REG6.ContactType=ContactType.Frictional

CONT_REG6.FrictionCoefficient = 0.2

CONT_REG6.SmallSliding = ContactSmallSlidingType.Off

CONT_REG6.UpdateStiffness = UpdateContactStiffness.Never

CMD6=CONT_REG6.AddCommandSnippet()

# Add missing contact keyopt and Archard Wear Model in workbench using a command snippet.

AWM6 = '''keyopt,cid,9,5

rmodif,cid,10,0.00

rmodif,cid,23,0.001'''

CMD6.AppendText(AWM6)

# Add contact tool.

#CONT_TOOL = CONN_GRP.AddContactTool()

#CONT_TOOL.AddPenetration()

#CONT_TOOL.AddStatus()

#CONT_TOOL.GenerateInitialContactResults()

# Generate mesh.

Hex_Method = MSH.AddAutomaticMethod()

Hex_Method.Location = all_bodies

Hex_Method.Method = MethodType.HexDominant

BODY_SIZING1=MSH.AddSizing()

BODY_SIZING1.Location=bodies_5

BODY_SIZING1.ElementSize = Quantity(15, "mm")

BODY_SIZING2=MSH.AddSizing()

BODY_SIZING2.Location=shank

BODY_SIZING2.ElementSize = Quantity(7, "mm")

Face_Meshing = MSH.AddFaceMeshing()

Face_Meshing.Location = shank_face

Face_Meshing.MappedMesh = False

Sweep_Method = MSH.AddAutomaticMethod()

Sweep_Method.Location = shank

Sweep_Method.Method = MethodType.Sweep

Sweep_Method.SourceTargetSelection = 2

Sweep_Method.SourceLocation = shank_face

Sweep_Method.TargetLocation = shank_face2

MSH.GenerateMesh()

# Set up analysis settings.

STAT_STRUC_ANA_SETTING.NumberOfSteps = 4

step_index_list = [1]

with Transaction():

for step_index in step_index_list:

STAT_STRUC_ANA_SETTING.SetAutomaticTimeStepping(step_index, AutomaticTimeStepping.Off)

STAT_STRUC_ANA_SETTING.Activate()

step_index_list = [1]

with Transaction():

for step_index in step_index_list:

STAT_STRUC_ANA_SETTING.SetNumberOfSubSteps(step_index, 2)

STAT_STRUC_ANA_SETTING.Activate()

STAT_STRUC_ANA_SETTING.SolverType = SolverType.Direct

STAT_STRUC_ANA_SETTING.SolverPivotChecking = SolverPivotChecking.Off

# Insert loading and BC.

FIX_SUP=STAT_STRUC.AddFixedSupport()

FIX_SUP.Location=block2_surface

Tabular_Force = STAT_STRUC.AddForce()

Tabular_Force.Location = bottom_surface

Tabular_Force.DefineBy = LoadDefineBy.Components

Tabular_Force.XComponent.Inputs[0].DiscreteValues = [Quantity('0[s]'),Quantity('1[s]'), \

Quantity('2[s]'),Quantity('3[s]'),Quantity('4[s]')]

Tabular_Force.XComponent.Output.DiscreteValues = [Quantity('0[N]'),Quantity('0[N]'), \

Quantity('5.e+005[N]'),Quantity('0[N]'),Quantity('-5.e+005[N]')]

Bolt_Pretension = STAT_STRUC.AddBoltPretension()

Bolt_Pretension.Location = shank_surface

Bolt_Pretension.Preload.Inputs[0].DiscreteValues = [Quantity('1[s]'),Quantity('2[s]'), \

Quantity('3[s]'),Quantity('4[s]')]

Bolt_Pretension.Preload.Output.DiscreteValues = [Quantity('6.1363e+005[N]'), \

Quantity('0 [N]'),Quantity('0 [N]'),Quantity('0[N]')]

Bolt_Pretension.SetDefineBy(2,BoltLoadDefineBy.Lock)

Bolt_Pretension.SetDefineBy(3,BoltLoadDefineBy.Lock)

Bolt_Pretension.SetDefineBy(4,BoltLoadDefineBy.Lock)

# Insert results.

Post_Contact_Tool = STAT_STRUC_SOLN.AddContactTool()

Post_Contact_Tool.ScopingMethod = GeometryDefineByType.Worksheet

Bolt_Tool = STAT_STRUC_SOLN.AddBoltTool()

Bolt_Working_Load = Bolt_Tool.AddWorkingLoad()

Total_Deformation = STAT_STRUC_SOLN.AddTotalDeformation()

Equivalent_stress_1 = STAT_STRUC_SOLN.AddEquivalentStress()

Equivalent_stress_2 = STAT_STRUC_SOLN.AddEquivalentStress()

Equivalent_stress_2.Location = shank

Force_Reaction_1 = STAT_STRUC_SOLN.AddForceReaction()

Force_Reaction_1.BoundaryConditionSelection = FIX_SUP

Moment_Reaction_2 = STAT_STRUC_SOLN.AddMomentReaction()

Moment_Reaction_2.BoundaryConditionSelection = FIX_SUP

# Set number of processors to 6 using DANSYS. (Optional)

# Num_Cores = STAT_STRUC.SolveConfiguration.SolveProcessSettings.MaxNumberOfCores

# STAT_STRUC.SolveConfiguration.SolveProcessSettings.MaxNumberOfCores = 6

# Solve and validate the results.

STAT_STRUC_SOLN.Solve(True)

STAT_STRUC_SS=STAT_STRUC_SOLN.Status

# Set the isometric view and zoom to fit.

cam = Graphics.Camera

cam.SetSpecificViewOrientation(ViewOrientationType.Iso)

cam.SetFit()

mechdir = STAT_STRUC.Children[0].SolverFilesDirectory

export_path = os.path.join(mechdir, "contact_status.png")

Post_Contact_Tool.Children[0].Activate()

Graphics.ExportImage(export_path, GraphicsImageExportFormat.PNG)

my_results_details = {

"Total_Deformation": str(Total_Deformation.Maximum),

"Equivalent_Stress1": str(Equivalent_stress_1.Maximum),

"Equivalent_Stress2": str(Equivalent_stress_2.Maximum),

}

json.dumps(my_results_details)

"""

)

print(output)

{"Equivalent_Stress1": "1947.6520097150596 [MPa]", "Total_Deformation": "0.38464899275987519 [mm]", "Equivalent_Stress2": "1947.6520097150596 [MPa]"}

Initialize the variable needed for the image directory#

Set the image_dir variable for later use.

Make the variable compatible for Windows, Linux, and Docker containers.

# image_directory_modified = project_directory.replace("\\", "\\\\")

mechanical.run_python_script(f"image_dir=ExtAPI.DataModel.AnalysisList[0].WorkingDir")

# Verify the path for image directory.

result_image_dir_server = mechanical.run_python_script(f"image_dir")

print(f"Images are stored on the server at: {result_image_dir_server}")

Images are stored on the server at: /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/

Download the image and plot#

Download one image file from the server to the current working directory and plot using matplotlib.

def get_image_path(image_name):

return os.path.join(result_image_dir_server, image_name)

def display_image(path):

print(f"Printing {path} using matplotlib")

image1 = mpimg.imread(path)

plt.figure(figsize=(15, 15))

plt.axis("off")

plt.imshow(image1)

plt.show()

image_name = "contact_status.png"

image_path_server = get_image_path(image_name)

if image_path_server != "":

current_working_directory = os.getcwd()

local_file_path_list = mechanical.download(

image_path_server, target_dir=current_working_directory

)

image_local_path = local_file_path_list[0]

print(f"Local image path : {image_local_path}")

display_image(image_local_path)

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/contact_status.png to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/contact_status.png: 0%| | 0.00/98.1k [00:00<?, ?B/s]

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/contact_status.png to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/contact_status.png: 100%|██████████| 98.1k/98.1k [00:00<00:00, 604MB/s]

Local image path : /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/contact_status.png

Printing /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/contact_status.png using matplotlib

Download output file from solve and print contents#

Download the solve.out file from the server to the current working

directory and print the contents. Remove the solve.out file.

def get_solve_out_path(mechanical):

"""Get the solve out path and return."""

solve_out_path = ""

for file_path in mechanical.list_files():

if file_path.find("solve.out") != -1:

solve_out_path = file_path

break

return solve_out_path

def write_file_contents_to_console(path):

"""Write file contents to console."""

with open(path, "rt") as file:

for line in file:

print(line, end="")

solve_out_path = get_solve_out_path(mechanical)

if solve_out_path != "":

current_working_directory = os.getcwd()

mechanical.download(solve_out_path, target_dir=current_working_directory)

solve_out_local_path = os.path.join(current_working_directory, "solve.out")

write_file_contents_to_console(solve_out_local_path)

os.remove(solve_out_local_path)

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/solve.out to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/solve.out: 0%| | 0.00/78.8k [00:00<?, ?B/s]

Downloading dns:///127.0.0.1:10000:/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/solve.out to /home/runner/work/pymechanical-examples/pymechanical-examples/examples/basic/solve.out: 100%|██████████| 78.8k/78.8k [00:00<00:00, 380MB/s]

Ansys Mechanical Enterprise

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS MAPDL 2025 R2 LEGAL NOTICES *

***************************************************************

* *

* Copyright 1971-2025 Ansys, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of Ansys, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the Ansys, Inc. online documentation or the Ansys, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* Ansys, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* Ansys, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the Ansys, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the Ansys, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

2025 R2

Point Releases and Patches installed:

Ansys, Inc. License Manager 2025 R2

LS-DYNA 2025 R2

Core WB Files 2025 R2

Mechanical Products 2025 R2

***** MAPDL COMMAND LINE ARGUMENTS *****

BATCH MODE REQUESTED (-b) = NOLIST

INPUT FILE COPY MODE (-c) = COPY

DISTRIBUTED MEMORY PARALLEL REQUESTED

4 PARALLEL PROCESSES REQUESTED WITH SINGLE THREAD PER PROCESS

TOTAL OF 4 CORES REQUESTED

INPUT FILE NAME = /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/dummy.dat

OUTPUT FILE NAME = /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/solve.out

START-UP FILE MODE = NOREAD

STOP FILE MODE = NOREAD

RELEASE= 2025 R2 BUILD= 25.2 UP20250519 VERSION=LINUX x64

CURRENT JOBNAME=file0 20:50:54 JAN 05, 2026 CP= 0.233

PARAMETER _DS_PROGRESS = 999.0000000

/INPUT FILE= ds.dat LINE= 0

*** NOTE *** CP = 0.339 TIME= 20:50:54

The /CONFIG,NOELDB command is not valid in a distributed memory

parallel solution. Command is ignored.

*GET _WALLSTRT FROM ACTI ITEM=TIME WALL VALUE= 20.8483333

TITLE=

--Static Structural

ACT Extensions:

LSDYNA, 2025.2

5f463412-bd3e-484b-87e7-cbc0a665e474, wbex

SET PARAMETER DIMENSIONS ON _WB_PROJECTSCRATCH_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_PROJECTSCRATCH_DIR(1) = /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/

SET PARAMETER DIMENSIONS ON _WB_SOLVERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_SOLVERFILES_DIR(1) = /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/

SET PARAMETER DIMENSIONS ON _WB_USERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_USERFILES_DIR(1) = /tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/UserFiles/

--- Data in consistent NMM units. See Solving Units in the help system for more

MPA UNITS SPECIFIED FOR INTERNAL

LENGTH = MILLIMETERS (mm)

MASS = TONNE (Mg)

TIME = SECONDS (sec)

TEMPERATURE = CELSIUS (C)

TOFFSET = 273.0

FORCE = NEWTON (N)

HEAT = MILLIJOULES (mJ)

INPUT UNITS ARE ALSO SET TO MPA

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2025 R2 25.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 20:50:54 JAN 05, 2026 CP= 0.343

--Static Structural

***** MAPDL ANALYSIS DEFINITION (PREP7) *****

*********** Send User Defined Coordinate System(s) ***********

*********** Nodes for the whole assembly ***********

*********** Nodes for all Remote Points ***********

*********** Elements for Body 1 'Solid' ***********

*********** Elements for Body 3 'Solid' ***********

*********** Elements for Body 5 'Solid' ***********

*********** Elements for Body 7 'Solid' ***********

*********** Elements for Body 9 'Solid' ***********

*********** Elements for Body 11 'Solid' ***********

*********** Set Reference Temperature ***********

*********** Send Materials ***********

*********** Create Contact "Contact Region" ***********

Real Constant Set For Above Contact Is 13 & 12

*********** Create Contact "Contact Region 2" ***********

Real Constant Set For Above Contact Is 15 & 14

*********** Create Contact "Contact Region 3" ***********

Real Constant Set For Above Contact Is 17 & 16

*********** Create Contact "Contact Region 4" ***********

Real Constant Set For Above Contact Is 19 & 18

*********** Create Contact "Contact Region 5" ***********

Real Constant Set For Above Contact Is 21 & 20

*********** Create Contact "Contact Region 6" ***********

Real Constant Set For Above Contact Is 23 & 22

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Element Component ***********

*********** Send Named Selection as Element Component ***********

*********** Send Named Selection as Element Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Fixed Supports ***********

*********** Define Force Using Surface Effect Elements ***********

*********** Create Bolt Pretension "Bolt Pretension" ***********

CREATE COMPONENT CMEBOLT FROM PRETENSION ELEMENTS

CREATE COMPONENT CMNBOLT FROM PRETENSION NODES

***** ROUTINE COMPLETED ***** CP = 0.982

--- Number of total nodes = 20349

--- Number of contact elements = 4628

--- Number of spring elements = 0

--- Number of bearing elements = 0

--- Number of solid elements = 4430

--- Number of condensed parts = 0

--- Number of total elements = 9188

*GET _WALLBSOL FROM ACTI ITEM=TIME WALL VALUE= 20.8483333

****************************************************************************

************************* SOLUTION ********************************

****************************************************************************

***** MAPDL SOLUTION ROUTINE *****

PERFORM A STATIC ANALYSIS

THIS WILL BE A NEW ANALYSIS

EQUATION PIVOT CHECKING LOGIC WILL BE DISABLED

PRINT EQUATION PIVOT INFO ONCE PER LOADSTEP

PARAMETER _THICKRATIO = 0.6670000000

USE SPARSE MATRIX DIRECT SOLVER

CONTACT INFORMATION PRINTOUT LEVEL 1

DO NOT COMBINE ELEMENT MATRIX FILES (.emat) AFTER DISTRIBUTED PARALLEL SOLUTION

DO NOT COMBINE ELEMENT SAVE DATA FILES (.esav) AFTER DISTRIBUTED PARALLEL SOLUTION

NLDIAG: Nonlinear diagnostics CONT option is set to ON.

Writing frequency : each ITERATION.

DEFINE RESTART CONTROL FOR LOADSTEP LAST

AT FREQUENCY OF LAST AND NUMBER FOR OVERWRITE IS -1

DELETE RESTART FILES OF ENDSTEP

****************************************************

******************* SOLVE FOR LS 1 OF 4 ****************

SELECT FOR ITEM=TYPE COMPONENT=

IN RANGE 24 TO 24 STEP 1

98 ELEMENTS (OF 9188 DEFINED) SELECTED BY ESEL COMMAND.

SELECT ALL NODES HAVING ANY ELEMENT IN ELEMENT SET.

337 NODES (OF 20349 DEFINED) SELECTED FROM

98 SELECTED ELEMENTS BY NSLE COMMAND.

SPECIFIED SURFACE LOAD PRES FOR ALL SELECTED ELEMENTS LKEY = 1 KVAL = 1

SET ACCORDING TO TABLE PARAMETER = _LOADVARI153X

SPECIFIED SURFACE LOAD PRES FOR ALL SELECTED ELEMENTS LKEY = 2 KVAL = 1

VALUES = 0.0000 0.0000 0.0000 0.0000

SPECIFIED SURFACE LOAD PRES FOR ALL SELECTED ELEMENTS LKEY = 3 KVAL = 1

VALUES = 0.0000 0.0000 0.0000 0.0000

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 20349 STEP 1

20349 NODES (OF 20349 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 11845 STEP 1

9188 ELEMENTS (OF 9188 DEFINED) SELECTED BY ESEL COMMAND.

PRINTOUT RESUMED BY /GOP

SPECIFIED NODAL LOAD FX FOR SELECTED NODES 20219 TO 20219 BY 1

REAL= 613630.000 IMAG= 0.00000000

DO NOT USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE 2 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 2 SUBSTEPS AS A MAXIMUM

USE 2 SUBSTEPS AS A MINIMUM

TIME= 1.0000

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EANG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE ETMP ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE VENG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE STRS ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPEL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPPL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE CONT ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

*GET ANSINTER_ FROM ACTI ITEM=INT VALUE= 0.00000000

*IF ANSINTER_ ( = 0.00000 ) NE

0 ( = 0.00000 ) THEN

*ENDIF

*** NOTE *** CP = 1.123 TIME= 20:50:54

The automatic domain decomposition logic has selected the MESH domain

decomposition method with 4 processes per solution.

***** MAPDL SOLVE COMMAND *****

*** WARNING *** CP = 1.161 TIME= 20:50:54

Element shape checking is currently inactive. Issue SHPP,ON or

SHPP,WARN to reactivate, if desired.

*** NOTE *** CP = 1.208 TIME= 20:50:54

The model data was checked and warning messages were found.

Please review output or errors file (

/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/fil

le0.err ) for these warning messages.

*** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***

--- GIVE SUGGESTIONS AND RESET THE KEY OPTIONS ---

ELEMENT TYPE 1 IS SOLID187. IT IS NOT ASSOCIATED WITH FULLY INCOMPRESSIBLE

HYPERELASTIC MATERIALS. NO SUGGESTION IS AVAILABLE AND NO RESETTING IS NEEDED.

ELEMENT TYPE 2 IS SOLID186. KEYOPT(2)=0 IS SUGGESTED AND HAS BEEN RESET.

KEYOPT(1-12)= 0 0 0 0 0 0 0 0 0 0 0 0

ELEMENT TYPE 3 IS SOLID187. IT IS NOT ASSOCIATED WITH FULLY INCOMPRESSIBLE

HYPERELASTIC MATERIALS. NO SUGGESTION IS AVAILABLE AND NO RESETTING IS NEEDED.

ELEMENT TYPE 4 IS SOLID186. KEYOPT(2)=0 IS SUGGESTED AND HAS BEEN RESET.

KEYOPT(1-12)= 0 0 0 0 0 0 0 0 0 0 0 0

ELEMENT TYPE 5 IS SOLID187. IT IS NOT ASSOCIATED WITH FULLY INCOMPRESSIBLE

HYPERELASTIC MATERIALS. NO SUGGESTION IS AVAILABLE AND NO RESETTING IS NEEDED.

ELEMENT TYPE 6 IS SOLID186. KEYOPT(2)=0 IS SUGGESTED AND HAS BEEN RESET.

KEYOPT(1-12)= 0 0 0 0 0 0 0 0 0 0 0 0

ELEMENT TYPE 7 IS SOLID187. IT IS NOT ASSOCIATED WITH FULLY INCOMPRESSIBLE

HYPERELASTIC MATERIALS. NO SUGGESTION IS AVAILABLE AND NO RESETTING IS NEEDED.

ELEMENT TYPE 8 IS SOLID186. KEYOPT(2)=0 IS SUGGESTED AND HAS BEEN RESET.

KEYOPT(1-12)= 0 0 0 0 0 0 0 0 0 0 0 0

ELEMENT TYPE 9 IS SOLID187. IT IS NOT ASSOCIATED WITH FULLY INCOMPRESSIBLE

HYPERELASTIC MATERIALS. NO SUGGESTION IS AVAILABLE AND NO RESETTING IS NEEDED.

ELEMENT TYPE 10 IS SOLID186. KEYOPT(2)=0 IS SUGGESTED AND HAS BEEN RESET.

KEYOPT(1-12)= 0 0 0 0 0 0 0 0 0 0 0 0

ELEMENT TYPE 11 IS SOLID186. KEYOPT(2)=0 IS SUGGESTED AND HAS BEEN RESET.

KEYOPT(1-12)= 0 0 0 0 0 0 0 0 0 0 0 0

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2025 R2 25.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 20:50:54 JAN 05, 2026 CP= 1.221

--Static Structural

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . UX UY UZ

ANALYSIS TYPE . . . . . . . . . . . . . . . . .STATIC (STEADY-STATE)

OFFSET TEMPERATURE FROM ABSOLUTE ZERO . . . . . 273.15

EQUATION SOLVER OPTION. . . . . . . . . . . . .SPARSE

NEWTON-RAPHSON OPTION . . . . . . . . . . . . .PROGRAM CHOSEN

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** WARNING *** CP = 1.261 TIME= 20:50:54

Material number 24 (used by element 11618) should normally have at

least one MP or one TB type command associated with it. Output of

energy by material may not be available.

*** NOTE *** CP = 1.271 TIME= 20:50:54

The step data was checked and warning messages were found.

Please review output or errors file (

/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/fil

le0.err ) for these warning messages.

*** NOTE *** CP = 1.271 TIME= 20:50:54

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

*WARNING*: Some MPC/Lagrange based elements (e.g.7568) in real constant

set 15 overlap with other MPC/Lagrange based elements (e.g.9562) in

real constant set 21 which can cause overconstraint.

*** NOTE *** CP = 2.294 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 12 and contact element type 12 has been set up. The

companion pair has real constant set ID 13. Both pairs should have

the same behavior.

*WARNING*: The contact pairs have similar mesh patterns which can cause

overconstraint. MAPDL will deactivate the current pair and keep its

companion pair.

Contact algorithm: Augmented Lagrange method

Contact detection at: Gauss integration point

Contact stiffness factor FKN 1.0000

The resulting initial contact stiffness 0.18596E+06

Default penetration tolerance factor FTOLN 0.10000

The resulting penetration tolerance 1.3817

Max. initial friction coefficient MU 0.20000

Default tangent stiffness factor FKT 1.0000

*** WARNING *** CP = 2.294 TIME= 20:50:55

It is highly recommended to set KEYOPT(10)=0 (update contact stiffness

at each iteration) in order to achieve better convergence.

Use constant contact stiffness

Default Max. friction stress TAUMAX 0.10000E+21

Average contact surface length 14.016

Average contact pair depth 13.817

Average target surface length 13.943

Default pinball region factor PINB 1.0000

The resulting pinball region 13.817

Contact offset is included. Initial geometric penetration is excluded.

*** NOTE *** CP = 2.294 TIME= 20:50:55

Max. Initial penetration 0 was detected between contact element 7188

and target element 7394.

****************************************

*** NOTE *** CP = 2.294 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 13 and contact element type 12 has been set up. The

companion pair has real constant set ID 12. Both pairs should have

the same behavior.

MAPDL will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Contact algorithm: Augmented Lagrange method

Contact detection at: Gauss integration point

Contact stiffness factor FKN 1.0000

The resulting initial contact stiffness 0.18596E+06

Default penetration tolerance factor FTOLN 0.10000

The resulting penetration tolerance 1.3981

Max. initial friction coefficient MU 0.20000

Default tangent stiffness factor FKT 1.0000

*WARNING*: It is highly recommended to set KEYOPT(10)=0 (update contact

stiffness at each iteration) in order to achieve better convergence.

Use constant contact stiffness

Default Max. friction stress TAUMAX 0.10000E+21

Average contact surface length 14.007

Average contact pair depth 13.981

Average target surface length 13.942

Default pinball region factor PINB 1.0000

The resulting pinball region 13.981

Contact offset is included. Initial geometric penetration is excluded.

*** NOTE *** CP = 2.295 TIME= 20:50:55

Max. Initial penetration 0 was detected between contact element 7288

and target element 7090.

****************************************

*** NOTE *** CP = 2.295 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 14 and contact element type 14 has been set up. The

companion pair has real constant set ID 15. Both pairs should have

the same behavior.

MAPDL will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Auto surface constraint is built

Contact algorithm: MPC based approach

*** NOTE *** CP = 2.295 TIME= 20:50:55

Contact related postprocess items (ETABLE, pressure ...) are not

available.

Contact detection at: nodal point (normal to target surface)

MPC will be built internally to handle bonded contact.

Average contact surface length 13.531

Average contact pair depth 9.0953

Average target surface length 6.3865

Default pinball region factor PINB 0.25000

The resulting pinball region 2.2738

Default target edge extension factor TOLS 2.0000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

*** NOTE *** CP = 2.295 TIME= 20:50:55

Max. Initial penetration 0.684961413 was detected between contact

element 7557 and target element 8579.

You may move entire target surface by : x= 3.574949984E-16, y=

-0.262123383, z= 0.632821831,to reduce initial penetration.

****************************************

*** NOTE *** CP = 2.295 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 15 and contact element type 14 has been set up. The

companion pair has real constant set ID 14. Both pairs should have

the same behavior.

MAPDL will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Auto surface constraint is built

Distributed constraint is built

Contact algorithm: MPC based approach

*** NOTE *** CP = 2.295 TIME= 20:50:55

Contact related postprocess items (ETABLE, pressure ...) are not

available.

Contact detection at: nodal point (normal to target surface)

MPC will be built internally to handle bonded contact.

*WARNING*: Certain contact elements (for example 8395&10389) overlap

each other. Overconstraint may occur.

Average contact surface length 6.4480

Average contact pair depth 5.1166

Average target surface length 13.388

Default pinball region factor PINB 0.25000

The resulting pinball region 1.2792

Default target edge extension factor TOLS 2.0000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

*** NOTE *** CP = 2.295 TIME= 20:50:55

Max. Initial penetration 0.675803228 was detected between contact

element 7843 and target element 7518.

You may move entire target surface by : x= 3.618027317E-02, y=

-0.234296751, z= -0.632855452,to reduce initial penetration.

*WARNING*: The geometric gap/penetration may be too large. Increase

pinball radius if it is a true geometric gap/penetration. Decrease

pinball if it is a false one.

****************************************

*** NOTE *** CP = 2.295 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 16 and contact element type 16 has been set up. The

companion pair has real constant set ID 17. Both pairs should have

the same behavior.

MAPDL will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Contact algorithm: Augmented Lagrange method

Contact detection at: Gauss integration point

Contact stiffness factor FKN 1.0000

The resulting initial contact stiffness 0.21483E+06

Default penetration tolerance factor FTOLN 0.10000

The resulting penetration tolerance 1.2103

Max. initial friction coefficient MU 0.20000

Default tangent stiffness factor FKT 1.0000

*WARNING*: It is highly recommended to set KEYOPT(10)=0 (update contact

stiffness at each iteration) in order to achieve better convergence.

Use constant contact stiffness

Default Max. friction stress TAUMAX 0.10000E+21

Average contact surface length 14.017

Average contact pair depth 12.103

Average target surface length 14.211

Default pinball region factor PINB 1.0000

The resulting pinball region 12.103

Contact offset is included. Initial geometric penetration is excluded.

*** NOTE *** CP = 2.295 TIME= 20:50:55

Max. Initial penetration 0 was detected between contact element 9324

and target element 9452.

****************************************

*** NOTE *** CP = 2.295 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 17 and contact element type 16 has been set up. The

companion pair has real constant set ID 16. Both pairs should have

the same behavior.

MAPDL will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Contact algorithm: Augmented Lagrange method

Contact detection at: Gauss integration point

Contact stiffness factor FKN 1.0000

The resulting initial contact stiffness 0.21483E+06

Default penetration tolerance factor FTOLN 0.10000

The resulting penetration tolerance 0.44258

Max. initial friction coefficient MU 0.20000

Default tangent stiffness factor FKT 1.0000

*WARNING*: It is highly recommended to set KEYOPT(10)=0 (update contact

stiffness at each iteration) in order to achieve better convergence.

Use constant contact stiffness

Default Max. friction stress TAUMAX 0.10000E+21

Average contact surface length 14.576

Average contact pair depth 4.4258

Average target surface length 13.943

Default pinball region factor PINB 1.0000

The resulting pinball region 4.4258

Contact offset is included. Initial geometric penetration is excluded.

*** NOTE *** CP = 2.295 TIME= 20:50:55

Max. Initial penetration 0 was detected between contact element 9424

and target element 9273.

****************************************

*** NOTE *** CP = 2.295 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 18 and contact element type 18 has been set up. The

companion pair has real constant set ID 19. Both pairs should have

the same behavior.

MAPDL will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Auto surface constraint is built

Contact algorithm: MPC based approach

*** NOTE *** CP = 2.295 TIME= 20:50:55

Contact related postprocess items (ETABLE, pressure ...) are not

available.

Contact detection at: nodal point (normal to target surface)

MPC will be built internally to handle bonded contact.

Average contact surface length 14.393

Average contact pair depth 4.4329

Average target surface length 12.238

Default pinball region factor PINB 0.25000

The resulting pinball region 1.1082

Default target edge extension factor TOLS 2.0000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

*** NOTE *** CP = 2.295 TIME= 20:50:55

Max. Initial penetration 5.684341886E-14 was detected between contact

element 9472 and target element 9504.

****************************************

*** NOTE *** CP = 2.295 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 19 and contact element type 18 has been set up. The

companion pair has real constant set ID 18. Both pairs should have

the same behavior.

MAPDL will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Auto surface constraint is built

Distributed constraint is built

Contact algorithm: MPC based approach

*** NOTE *** CP = 2.295 TIME= 20:50:55

Contact related postprocess items (ETABLE, pressure ...) are not

available.

Contact detection at: nodal point (normal to target surface)

MPC will be built internally to handle bonded contact.

*WARNING*: Certain contact elements (for example 9498&9550) overlap

each other. Overconstraint may occur.

Average contact surface length 12.576

Average contact pair depth 12.199

Average target surface length 14.266

Default pinball region factor PINB 0.25000

The resulting pinball region 3.0498

Default target edge extension factor TOLS 2.0000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

*** NOTE *** CP = 2.296 TIME= 20:50:55

Max. Initial penetration 1.136868377E-13 was detected between contact

element 9485 and target element 9459.

****************************************

*** NOTE *** CP = 2.296 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 20 and contact element type 20 has been set up. The

companion pair has real constant set ID 21. Both pairs should have

the same behavior.

MAPDL will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Auto surface constraint is built

Distributed constraint is built

Contact algorithm: MPC based approach

*** NOTE *** CP = 2.296 TIME= 20:50:55

Contact related postprocess items (ETABLE, pressure ...) are not

available.

Contact detection at: nodal point (normal to target surface)

MPC will be built internally to handle bonded contact.

*WARNING*: Certain contact elements (for example 9553&9490) overlap

each other. Overconstraint may occur.

Average contact surface length 13.088

Average contact pair depth 6.7345

Average target surface length 6.3865

Default pinball region factor PINB 0.25000

The resulting pinball region 1.6836

Default target edge extension factor TOLS 2.0000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

*** NOTE *** CP = 2.296 TIME= 20:50:55

Max. Initial penetration 1.28495889 was detected between contact

element 9541 and target element 11131.

You may move entire target surface by : x= 1.224539025E-15, y=

-1.18655332, z= -0.493163843,to reduce initial penetration.

*WARNING*: The geometric gap/penetration may be too large. Increase

pinball radius if it is a true geometric gap/penetration. Decrease

pinball if it is a false one.

****************************************

*** NOTE *** CP = 2.296 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 21 and contact element type 20 has been set up. The

companion pair has real constant set ID 20. Both pairs should have

the same behavior.

MAPDL will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Auto surface constraint is built

Distributed constraint is built

Contact algorithm: MPC based approach

*** NOTE *** CP = 2.296 TIME= 20:50:55

Contact related postprocess items (ETABLE, pressure ...) are not

available.

Contact detection at: nodal point (normal to target surface)

MPC will be built internally to handle bonded contact.

Average contact surface length 6.4480

Average contact pair depth 5.1166

Average target surface length 12.889

Default pinball region factor PINB 0.25000

The resulting pinball region 1.2792

Default target edge extension factor TOLS 2.0000

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

*** NOTE *** CP = 2.296 TIME= 20:50:55

Max. Initial penetration 1.2132628 was detected between contact

element 10303 and target element 9517.

You may move entire target surface by : x= 2.447930752E-02, y=

1.1355368, z= 0.426571867,to reduce initial penetration.

*WARNING*: The detected Max. Penetration is close to the pair based

pinball. Please verify the pinball radius carefully.

*WARNING*: The geometric gap/penetration may be too large. Increase

pinball radius if it is a true geometric gap/penetration. Decrease

pinball if it is a false one.

****************************************

*** NOTE *** CP = 2.296 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 22 and contact element type 22 has been set up. The

companion pair has real constant set ID 23. Both pairs should have

the same behavior.

*WARNING*: The contact pairs have similar mesh patterns which can cause

overconstraint. MAPDL will deactivate the current pair and keep its

companion pair.

Contact algorithm: Augmented Lagrange method

Contact detection at: Gauss integration point

Contact stiffness factor FKN 1.0000

The resulting initial contact stiffness 0.18035E+06

Default penetration tolerance factor FTOLN 0.10000

The resulting penetration tolerance 1.4416

Max. initial friction coefficient MU 0.20000

Default tangent stiffness factor FKT 1.0000

*WARNING*: It is highly recommended to set KEYOPT(10)=0 (update contact

stiffness at each iteration) in order to achieve better convergence.

Use constant contact stiffness

Default Max. friction stress TAUMAX 0.10000E+21

Average contact surface length 14.016

Average contact pair depth 14.416

Average target surface length 13.943

Default pinball region factor PINB 1.0000

The resulting pinball region 14.416

Contact offset is included. Initial geometric penetration is excluded.

*** NOTE *** CP = 2.296 TIME= 20:50:55

Max. Initial penetration 0 was detected between contact element 11318

and target element 11518.

****************************************

*** NOTE *** CP = 2.296 TIME= 20:50:55

Symmetric Deformable- deformable contact pair identified by real

constant set 23 and contact element type 22 has been set up. The

companion pair has real constant set ID 22. Both pairs should have

the same behavior.

MAPDL will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Contact algorithm: Augmented Lagrange method

Contact detection at: Gauss integration point

Contact stiffness factor FKN 1.0000

The resulting initial contact stiffness 0.18035E+06

Default penetration tolerance factor FTOLN 0.10000

The resulting penetration tolerance 1.2341

Max. initial friction coefficient MU 0.20000

Default tangent stiffness factor FKT 1.0000

*WARNING*: It is highly recommended to set KEYOPT(10)=0 (update contact

stiffness at each iteration) in order to achieve better convergence.

Use constant contact stiffness

Default Max. friction stress TAUMAX 0.10000E+21

Average contact surface length 14.007

Average contact pair depth 12.341

Average target surface length 13.942

Default pinball region factor PINB 1.0000

The resulting pinball region 12.341

Contact offset is included. Initial geometric penetration is excluded.

*** NOTE *** CP = 2.296 TIME= 20:50:55

Max. Initial penetration 0 was detected between contact element 11418

and target element 11218.

****************************************

*** WARNING *** CP = 2.296 TIME= 20:50:55

Overconstraint may occur for Lagrange multiplier or MPC based contact

algorithm.

The reasons for possible overconstraint are:

*** WARNING *** CP = 2.296 TIME= 20:50:55

Certain contact elements (for example 9553 & 9490) overlap with other.

****************************************

D I S T R I B U T E D D O M A I N D E C O M P O S E R

...Number of elements: 9188

...Number of nodes: 20349

...Decompose to 4 CPU domains

...Element load balance ratio = 1.661

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

TIME AT END OF THE LOAD STEP. . . . . . . . . . 1.0000

NUMBER OF SUBSTEPS. . . . . . . . . . . . . . . 2

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CONVERGENCE CONTROLS. . . . . . . . . . . . . .USE DEFAULTS

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

EANG ALL

ETMP ALL

VENG ALL

STRS ALL

EPEL ALL

EPPL ALL

CONT ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

>>>> PRETENSION ELEMENT STATUS <<<<

SECTION NAME PT.NODE --------STATUS-------------------- ----LOAD SOURCE----

25 20219 APPLIED PRELOAD FORCE= 0.61363E+06 F COMMAND

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 26, BY SOLUTION CONTROL LOGIC.

Range of element maximum matrix coefficients in global coordinates

Maximum = 29991749.6 at element 2613.

Minimum = 778765.908 at element 1157.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 80 SOLID187 0.005 0.000060

2 976 SOLID186 0.114 0.000117

3 103 SOLID187 0.006 0.000063

4 988 SOLID186 0.122 0.000123

5 10 SOLID187 0.001 0.000072

6 448 SOLID186 0.053 0.000119

7 10 SOLID187 0.001 0.000069

8 51 SOLID186 0.006 0.000125

9 4 SOLID187 0.000 0.000069

10 58 SOLID186 0.008 0.000132

11 1702 SOLID186 0.211 0.000124

12 200 CONTA174 0.042 0.000209

13 200 TARGE170 0.001 0.000006

14 868 CONTA174 0.027 0.000032

15 868 TARGE170 0.005 0.000006

16 115 CONTA174 0.007 0.000059

17 115 TARGE170 0.001 0.000005

18 30 CONTA174 0.006 0.000183

19 30 TARGE170 0.000 0.000006

20 852 CONTA174 0.027 0.000032

21 852 TARGE170 0.004 0.000005

22 200 CONTA174 0.041 0.000207

23 200 TARGE170 0.001 0.000005

24 98 SURF154 0.004 0.000036

25 130 PRETS179 0.000 0.000003

Time at end of element matrix formulation CP = 3.98980308.

ALL CURRENT MAPDL DATA WRITTEN TO FILE NAME= file.rdb

FOR POSSIBLE RESUME FROM THIS POINT

FORCE CONVERGENCE VALUE = 0.3068E+06 CRITERION= 1534.

DISTRIBUTED SPARSE MATRIX DIRECT SOLVER.

Number of equations = 55306, Maximum wavefront = 462

Memory allocated on only this MPI rank (rank 0)

-------------------------------------------------------------------

Equation solver memory allocated = 131.069 MB

Equation solver memory required for in-core mode = 125.583 MB

Equation solver memory required for out-of-core mode = 49.442 MB

Total (solver and non-solver) memory allocated = 820.131 MB

Total memory summed across all MPI ranks on this machines

-------------------------------------------------------------------

Equation solver memory allocated = 524.914 MB

Equation solver memory required for in-core mode = 503.789 MB

Equation solver memory required for out-of-core mode = 216.846 MB

Total (solver and non-solver) memory allocated = 2455.531 MB

*** NOTE *** CP = 4.344 TIME= 20:50:56

The Distributed Sparse Matrix Solver is currently running in the

in-core memory mode. This memory mode uses the most amount of memory

in order to avoid using the hard drive as much as possible, which most

often results in the fastest solution time. This mode is recommended

if enough physical memory is present to accommodate all of the solver

data.

curEqn= 14926 totEqn= 14926 Job CP sec= 4.831

Factor Done= 100% Factor Wall sec= 0.560 rate= 18.4 GFlops

Distributed sparse solver maximum pivot= 40670290.3 at node 1275 UX.

Distributed sparse solver minimum pivot= 213459.629 at node 12588 UZ.

Distributed sparse solver minimum pivot in absolute value= 213459.629

at node 12588 UZ.

DISP CONVERGENCE VALUE = 0.3397 CRITERION= 0.1699E-01

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.3397

DISP CONVERGENCE VALUE = 0.3397 CRITERION= 0.1699E-01

LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.3397

FORCE CONVERGENCE VALUE = 0.2063E+05 CRITERION= 1544.

EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.6386E-02

DISP CONVERGENCE VALUE = 0.6386E-02 CRITERION= 0.1721E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.6386E-02

FORCE CONVERGENCE VALUE = 0.1399E+05 CRITERION= 1543.

EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.3117E-02

DISP CONVERGENCE VALUE = 0.3117E-02 CRITERION= 0.1734E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.3117E-02

FORCE CONVERGENCE VALUE = 5726. CRITERION= 1542.

EQUIL ITER 4 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1599E-02

DISP CONVERGENCE VALUE = 0.1599E-02 CRITERION= 0.1738E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.1599E-02

FORCE CONVERGENCE VALUE = 3507. CRITERION= 1542.

EQUIL ITER 5 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.1299E-02

DISP CONVERGENCE VALUE = 0.1299E-02 CRITERION= 0.1740E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = -0.1299E-02

FORCE CONVERGENCE VALUE = 3181. CRITERION= 1542.

EQUIL ITER 6 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.3930E-03

DISP CONVERGENCE VALUE = 0.3930E-03 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = -0.3930E-03

FORCE CONVERGENCE VALUE = 721.5 CRITERION= 1542. <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 6

*** ELEMENT RESULT CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 80 SOLID187 0.005 0.000057

2 976 SOLID186 0.084 0.000087

3 103 SOLID187 0.006 0.000055

4 988 SOLID186 0.086 0.000087

5 10 SOLID187 0.001 0.000066

6 448 SOLID186 0.039 0.000088

7 10 SOLID187 0.001 0.000063

8 51 SOLID186 0.004 0.000086

9 4 SOLID187 0.000 0.000059

10 58 SOLID186 0.005 0.000091

11 1702 SOLID186 0.154 0.000090

12 200 CONTA174 0.012 0.000060

14 868 CONTA174 0.023 0.000026

16 115 CONTA174 0.004 0.000033

18 30 CONTA174 0.001 0.000019

20 852 CONTA174 0.016 0.000018

22 200 CONTA174 0.012 0.000058

24 98 SURF154 0.002 0.000025

*** NODAL LOAD CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 80 SOLID187 0.001 0.000014

2 976 SOLID186 0.015 0.000015

3 103 SOLID187 0.001 0.000014

4 988 SOLID186 0.015 0.000015

5 10 SOLID187 0.000 0.000016

6 448 SOLID186 0.007 0.000015

7 10 SOLID187 0.000 0.000015

8 51 SOLID186 0.001 0.000016

9 4 SOLID187 0.000 0.000015

10 58 SOLID186 0.001 0.000016

11 1702 SOLID186 0.028 0.000016

12 200 CONTA174 0.002 0.000008

14 868 CONTA174 0.003 0.000003

16 115 CONTA174 0.001 0.000005

18 30 CONTA174 0.000 0.000003

20 852 CONTA174 0.003 0.000003

22 200 CONTA174 0.001 0.000007

24 98 SURF154 0.000 0.000003

*** LOAD STEP 1 SUBSTEP 1 COMPLETED. CUM ITER = 6

*** TIME = 0.500000 TIME INC = 0.500000

FORCE CONVERGENCE VALUE = 6422. CRITERION= 3084.

DISP CONVERGENCE VALUE = 0.8183E-03 CRITERION= 0.1741E-01 <<< CONVERGED

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.8183E-03

DISP CONVERGENCE VALUE = 0.5675E-03 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.6935 SCALED MAX DOF INC = -0.5675E-03

FORCE CONVERGENCE VALUE = 1777. CRITERION= 3084. <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 1

*** LOAD STEP 1 SUBSTEP 2 COMPLETED. CUM ITER = 7

*** TIME = 1.00000 TIME INC = 0.500000

*** MAPDL BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

0.188 MB WRITTEN ON ELEMENT MATRIX FILE: file0.emat

7.562 MB WRITTEN ON ELEMENT SAVED DATA FILE: file0.esav

12.125 MB WRITTEN ON ASSEMBLED MATRIX FILE: file0.full

2.625 MB WRITTEN ON RESULTS FILE: file0.rst

*************** Write FE CONNECTORS *********

WRITE OUT CONSTRAINT EQUATIONS TO FILE= file.ce

****************************************************

*************** FINISHED SOLVE FOR LS 1 *************

****************************************************

******************* SOLVE FOR LS 2 OF 4 ****************

PRINTOUT RESUMED BY /GOP

DELETE ALL SPECIFIED NODAL LOADS FROM NODE 20219 TO 20219 BY 1

NUMBER OF NODAL LOADS DELETED= 1

*** WARNING *** CP = 13.872 TIME= 20:51:05

Table _FIX is an MAPDL reserved table name. It is used to constrain

structural degrees of freedom to their current displaced status. This

table should not be used for other purposes.

SPECIFIED CONSTRAINT UX FOR SELECTED NODES 20219 TO 20219 BY 1

SET ACCORDING TO TABLE PARAMETER = _FIX

USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE 1 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 10 SUBSTEPS AS A MAXIMUM

USE 1 SUBSTEPS AS A MINIMUM

TIME= 2.0000

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EANG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE ETMP ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE VENG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE STRS ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPEL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPPL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE CONT ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

***** MAPDL SOLVE COMMAND *****

*** WARNING *** CP = 13.992 TIME= 20:51:05

Material number 24 (used by element 11618) should normally have at

least one MP or one TB type command associated with it. Output of

energy by material may not be available.

*** NOTE *** CP = 14.001 TIME= 20:51:05

The step data was checked and warning messages were found.

Please review output or errors file (

/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/fil

le0.err ) for these warning messages.

*** NOTE *** CP = 14.002 TIME= 20:51:05

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2025 R2 25.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 20:51:05 JAN 05, 2026 CP= 14.148

--Static Structural

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 2

TIME AT END OF THE LOAD STEP. . . . . . . . . . 2.0000

AUTOMATIC TIME STEPPING . . . . . . . . . . . . ON

INITIAL NUMBER OF SUBSTEPS . . . . . . . . . 1

MAXIMUM NUMBER OF SUBSTEPS . . . . . . . . . 10

MINIMUM NUMBER OF SUBSTEPS . . . . . . . . . 1

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CONVERGENCE CONTROLS. . . . . . . . . . . . . .USE DEFAULTS

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

EANG ALL

ETMP ALL

VENG ALL

STRS ALL

EPEL ALL

EPPL ALL

CONT ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

>>>> PRETENSION ELEMENT STATUS <<<<

SECTION NAME PT.NODE --------STATUS-------------------- ----LOAD SOURCE----

25 20219 FIXED RELATIVE MOTION= 0.69603 D COMMAND

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 26, BY SOLUTION CONTROL LOGIC.

FORCE CONVERGENCE VALUE = 0.4900E+05 CRITERION= 3094.

DISP CONVERGENCE VALUE = 0.1807E-01 CRITERION= 0.1741E-01

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1807E-01

DISP CONVERGENCE VALUE = 0.1797E-01 CRITERION= 0.1741E-01

LINE SEARCH PARAMETER = 0.9945 SCALED MAX DOF INC = 0.1797E-01

FORCE CONVERGENCE VALUE = 0.3016E+05 CRITERION= 3121.

EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.7669E-02

DISP CONVERGENCE VALUE = 0.7154E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.9328 SCALED MAX DOF INC = 0.7154E-02

FORCE CONVERGENCE VALUE = 0.2484E+05 CRITERION= 3121.

EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.9772E-02

DISP CONVERGENCE VALUE = 0.9513E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.9735 SCALED MAX DOF INC = 0.9513E-02

FORCE CONVERGENCE VALUE = 0.2324E+05 CRITERION= 3127.

EQUIL ITER 4 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.8215E-02

DISP CONVERGENCE VALUE = 0.8214E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.9999 SCALED MAX DOF INC = 0.8214E-02

FORCE CONVERGENCE VALUE = 0.1743E+05 CRITERION= 3132.

EQUIL ITER 5 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.2882E-02

DISP CONVERGENCE VALUE = 0.2702E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.9373 SCALED MAX DOF INC = 0.2702E-02

FORCE CONVERGENCE VALUE = 0.1994E+05 CRITERION= 3135.

EQUIL ITER 6 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.2449E-02

DISP CONVERGENCE VALUE = 0.2449E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 1.000 SCALED MAX DOF INC = 0.2449E-02

FORCE CONVERGENCE VALUE = 8541. CRITERION= 3137.

EQUIL ITER 7 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.2838E-02

DISP CONVERGENCE VALUE = 0.2663E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.9383 SCALED MAX DOF INC = 0.2663E-02

FORCE CONVERGENCE VALUE = 7421. CRITERION= 3689.

EQUIL ITER 8 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1055E-02

DISP CONVERGENCE VALUE = 0.1045E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.9910 SCALED MAX DOF INC = 0.1045E-02

FORCE CONVERGENCE VALUE = 1992. CRITERION= 3766. <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 8

*** LOAD STEP 2 SUBSTEP 1 COMPLETED. CUM ITER = 15

*** TIME = 2.00000 TIME INC = 1.00000

****************************************************

*************** FINISHED SOLVE FOR LS 2 *************

****************************************************

******************* SOLVE FOR LS 3 OF 4 ****************

PRINTOUT RESUMED BY /GOP

DELETE ALL SPECIFIED NODAL LOADS FROM NODE 20219 TO 20219 BY 1

NUMBER OF NODAL LOADS DELETED= 0

SPECIFIED CONSTRAINT UX FOR SELECTED NODES 20219 TO 20219 BY 1

SET ACCORDING TO TABLE PARAMETER = _FIX

USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE 1 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 10 SUBSTEPS AS A MAXIMUM

USE 1 SUBSTEPS AS A MINIMUM

TIME= 3.0000

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EANG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE ETMP ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE VENG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE STRS ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPEL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EPPL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE CONT ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

***** MAPDL SOLVE COMMAND *****

*** WARNING *** CP = 25.044 TIME= 20:51:16

Material number 24 (used by element 11618) should normally have at

least one MP or one TB type command associated with it. Output of

energy by material may not be available.

*** NOTE *** CP = 25.053 TIME= 20:51:16

The step data was checked and warning messages were found.

Please review output or errors file (

/tmp/ANSYS.root.1/AnsysMechCFFB/Project_Mech_Files/StaticStructural/fil

le0.err ) for these warning messages.

*** NOTE *** CP = 25.053 TIME= 20:51:16

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2025 R2 25.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=LINUX x64 20:51:16 JAN 05, 2026 CP= 25.199

--Static Structural

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 3

TIME AT END OF THE LOAD STEP. . . . . . . . . . 3.0000

AUTOMATIC TIME STEPPING . . . . . . . . . . . . ON

INITIAL NUMBER OF SUBSTEPS . . . . . . . . . 1

MAXIMUM NUMBER OF SUBSTEPS . . . . . . . . . 10

MINIMUM NUMBER OF SUBSTEPS . . . . . . . . . 1

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . NO

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CONVERGENCE CONTROLS. . . . . . . . . . . . . .USE DEFAULTS

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

EANG ALL

ETMP ALL

VENG ALL

STRS ALL

EPEL ALL

EPPL ALL

CONT ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

>>>> PRETENSION ELEMENT STATUS <<<<

SECTION NAME PT.NODE --------STATUS-------------------- ----LOAD SOURCE----

25 20219 FIXED RELATIVE MOTION= 0.69603 D COMMAND

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 26, BY SOLUTION CONTROL LOGIC.

FORCE CONVERGENCE VALUE = 0.4901E+05 CRITERION= 3130.

DISP CONVERGENCE VALUE = 0.8320E-01 CRITERION= 0.1741E-01

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.8320E-01

DISP CONVERGENCE VALUE = 0.8089E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.9723E-01 SCALED MAX DOF INC = -0.8089E-02

FORCE CONVERGENCE VALUE = 0.2955E+06 CRITERION= 3129.

EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.4255E-01

DISP CONVERGENCE VALUE = 0.9246E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.2173 SCALED MAX DOF INC = -0.9246E-02

FORCE CONVERGENCE VALUE = 0.3337E+06 CRITERION= 3115.

EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.2286E-01

DISP CONVERGENCE VALUE = 0.6465E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.2828 SCALED MAX DOF INC = -0.6465E-02

FORCE CONVERGENCE VALUE = 0.2930E+06 CRITERION= 3105.

EQUIL ITER 4 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.1084E-01

DISP CONVERGENCE VALUE = 0.4775E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.4404 SCALED MAX DOF INC = -0.4775E-02

FORCE CONVERGENCE VALUE = 0.1942E+06 CRITERION= 3092.

EQUIL ITER 5 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.4768E-02

DISP CONVERGENCE VALUE = 0.4067E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.8529 SCALED MAX DOF INC = -0.4067E-02

FORCE CONVERGENCE VALUE = 0.5936E+05 CRITERION= 3082.

EQUIL ITER 6 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= -0.2242E-02

DISP CONVERGENCE VALUE = 0.2128E-02 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.9494 SCALED MAX DOF INC = -0.2128E-02

FORCE CONVERGENCE VALUE = 6509. CRITERION= 3079.

EQUIL ITER 7 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1042E-02

DISP CONVERGENCE VALUE = 0.9008E-03 CRITERION= 0.1741E-01 <<< CONVERGED

LINE SEARCH PARAMETER = 0.8647 SCALED MAX DOF INC = 0.9008E-03

FORCE CONVERGENCE VALUE = 3364. CRITERION= 3618. <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 7

*** LOAD STEP 3 SUBSTEP 1 COMPLETED. CUM ITER = 22

*** TIME = 3.00000 TIME INC = 1.00000

****************************************************

*************** FINISHED SOLVE FOR LS 3 *************

****************************************************

******************* SOLVE FOR LS 4 OF 4 ****************

PRINTOUT RESUMED BY /GOP

DELETE ALL SPECIFIED NODAL LOADS FROM NODE 20219 TO 20219 BY 1

NUMBER OF NODAL LOADS DELETED= 0

SPECIFIED CONSTRAINT UX FOR SELECTED NODES 20219 TO 20219 BY 1

SET ACCORDING TO TABLE PARAMETER = _FIX

USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE 1 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING: